At Powder Projects, we are continuously challenged to innovate by the needs of our clients.

These challenges have driven us to develop and improve a range of equipment and design expertise that can meet the exacting demands of the dairy and infant formula industry.

Milk Powder

Our experienced team prides itself in designing and installing powder blending equipment and engineering systems that solve the many complex challenges powder handling often possesses.

The characteristics of dairy powders vary significantly, the varying compositions and balance of nutrients determine how these powders flow, dissolve, leave sediments and suspensions, are sticky or not and the variabilities of bulk densities. Some are very delicate agglomerates, sensitive to mechanical handling, or ingredients can segregate or lose their homogeneity. No one powder is created equal – therefore they are all unique with unique characteristics and requirements.

Infant Formula

We have a wealth of experience in equipment design, powder conveying, hygiene design and deep cleaning of process equipment to produce Infant Formula every day.

Infant formulation work is a detailed and complex process. We are experienced in designing and validating plant equipment for:

Efficiency of production

Repeatability of blends

Hygienic design standards

Easy clean systems.

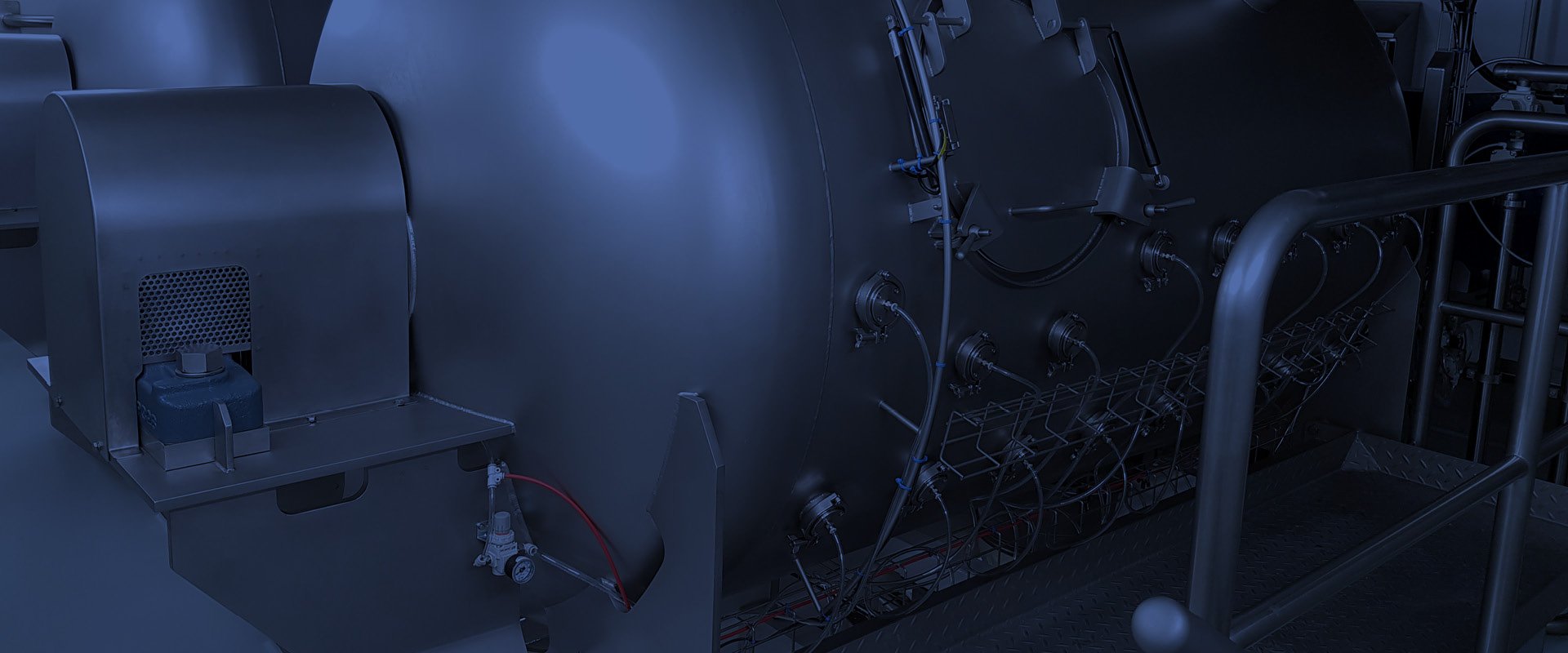

Our Equipment

We are continuously challenged to innovate by the needs of our clients. These challenges have driven us to develop and improve a range of equipment and design expertise that can meet the exacting demands of the dairy and infant formula industry.

We produce the following equipment solutions for high scale production.

25kg Manual and Robotic Depalletising

Ergonomic 25kg Kraft Removal Systems (Manual)

25kg Bag Sorting and Conveyor Systems

Plastic Liner UV Sterilisation Tunnels

Manual Bag Tipping Stations

25kg Automatic Bag Tipping (HBD25)

Forberg Twin Paddle Blending Tower Systems

Twin Vacuum Blending Low-Level System

Easy Clean Vacuum Transfer Vessels (Tool-Free Entry)

Easy Clean Sifters

Powder Pre-Gassing Systems.